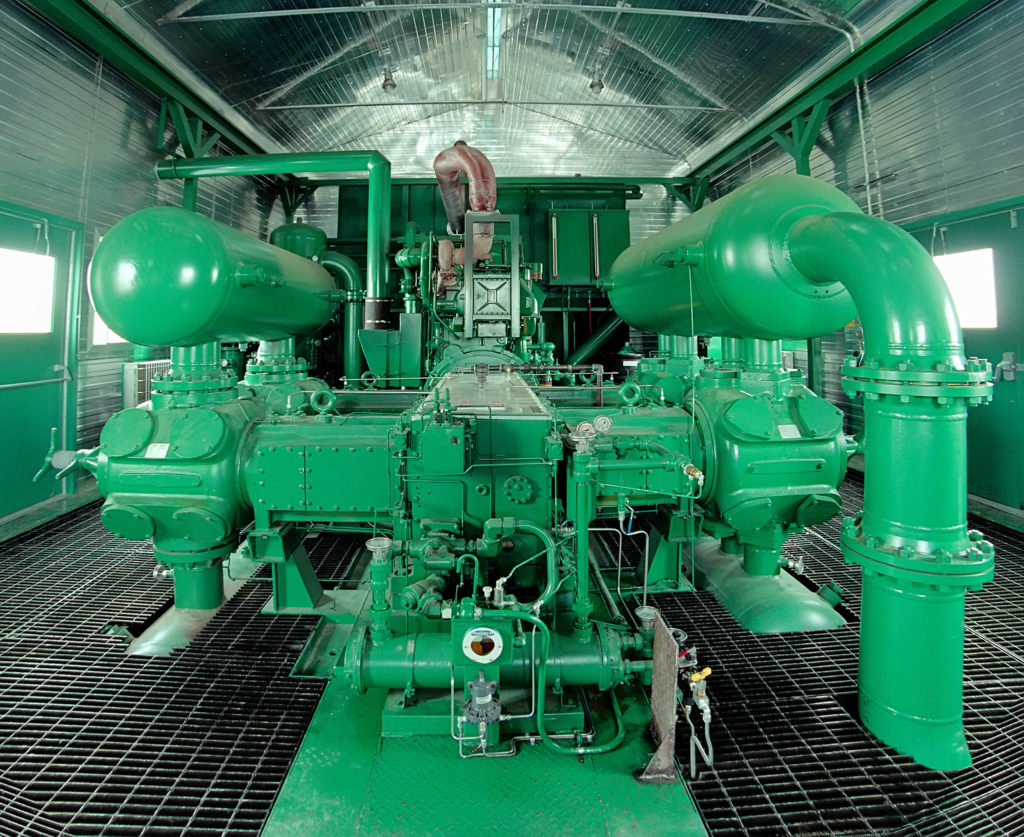

Large reciprocating compressors in the petrochemical, refining and natural gas plants can fail for a number of reasons. The paper will give a brief overview on why this happens.

The GPSA Data Book provides this summary: “Reciprocating compressors should be supplied with clean gas as they cannot satisfactorily handle liquids and solid particles that may be entrained in the gas. Liquids and solid particles tend to destroy cylinder lubrication and cause excessive wear. Liquids are noncompressible and their presence could rupture the compressor cylinder or cause other major damage.”1

Heinz Bloch’s book on Reciprocating Compressors 2 list four categories for foreign materials that destroy compressors and give clues of what to look for:

1. Liquid carryover

(slug flow, carryover from interstage coolers, flow changes)

2. Dirty gas

(solid particles act as grinding compounds and interference debris)

3. Carbon formation

(high temperatures, oils, and gases make carbonaceous debris)

4. Corrosive elements

(corrosion, erosion, and complex failure modes occur)

How does one overcome these potential failures? By sizing suction knockout pots for the worst case scenario and not the average scenario.

Internals for knockout pots, such as demister pads and their associated devices such as filters, are imperative and are an integral part of compressor P&ID design.

Call COSTELLO and our compressor specialist can come to your site to help resolve your compressor problems including general design, installation, and maintenance.

References:

1. GPSA Engineering Data Book, 12th Edition, Tulsa: Gas Processors Suppliers Association, 2004.

2. Reciprocating Compressors:: Operation and Maintenance 1st Edition by Heinz P. Bloch

Phone: 310-792-5870 Email: rcca@rccostello.com

Website: rccostello.com