Introduction

A new batch distillation project can be an overwhelming task for operating engineers in the field with many duties including plant operations. The list below gives one an idea on what should you know before you start a batch distillation project.

Summary

- Is the final product to be sold damaged by temperature? This infers that a vacuum may be required to lower the boiling point

- How hot does the still pot need to be? Will you be able to use 150 psig steam or hot oil? This determines the first utility, heating.

- How cold does the overhead condenser need to be? Will you use cooling tower water or chilled water? This is directly tied to column operating pressure.

- Is installed cost or operating cost more important to you? A short column with high reflux ratio can make the same separation as a tall column with low reflux ratio. The former has higher energy requirement and a lower installed cost while the latter has lower energy requirement and a higher installed cost.

- If this unit will be installed inside a building, do you have a height restriction?

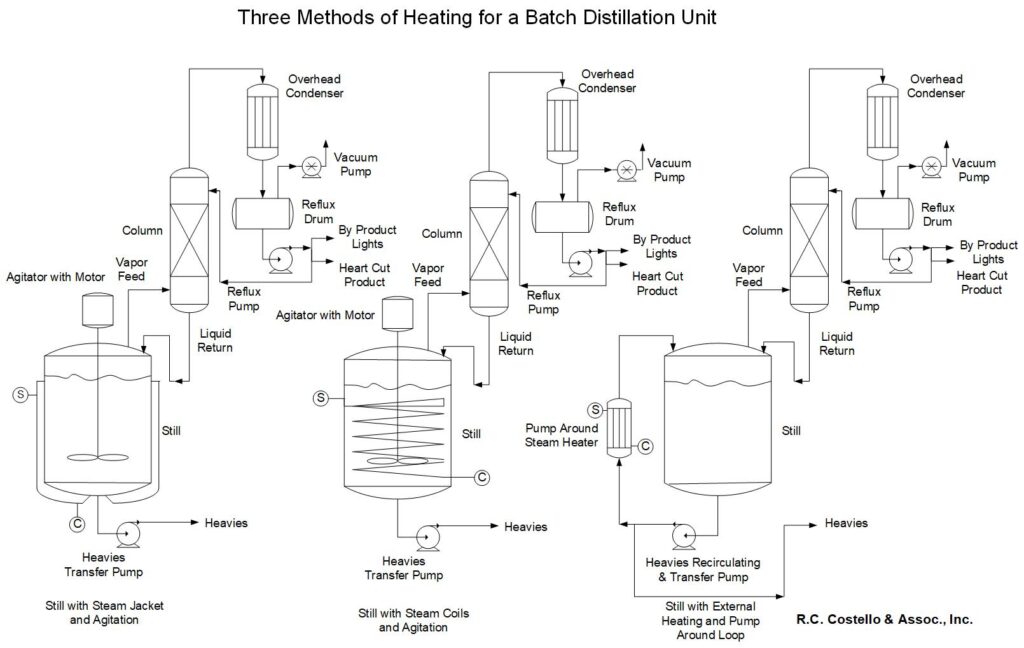

- How will you heat the pot?

- Internal coils

- External jacket or plate coils

- A pump around reboiler

- Or a combination

- How will you cool the pot at the end of a batch cycle? Similar to number 6 above.

- If you require an agitator to enhance heat transfer, what type of shaft seal do you require?

- Packed

- Single mechanical

- Double mechanical

- Magnetic drive so toxic vapors are not released into the plant.

- Do you have enough height at the bottom of the pot so that actual NPSH is greater than required NPSH at the highest operating temperature, lowest liquid level and lowest operating pressure for the pump specified with a pump around reboiler.

Conclusion

This not a complete list but should get you thinking about a new distillation process. Many times, you may wish to perform a chemical reaction before the distillation process in the same vessel.

For example, another type of system is the batch production of polyester resins where you react a dicarboxylic acid with a glycol to produce an unsaturated polyester. In this case the byproduct water must be distilled off continuously to keep the reaction moving to the right.

There are many things to consider when starting a new batch distillation project. COSTELLO can guide you through the many decisions you must make prior to starting a new distillation project.