Modular mini refineries are best utilized in emerging economies and in remote locations where gasoline, diesel and fuel oil are needed. The local crude oil is normally your lowest cost feed stock because the transportation costs are minimized.

Mini refineries with heavy crudes and low API gravity produce more fuel oil and less naphtha and diesel. Light crudes with high API gravity produce less fuel oil and more naphtha and diesel.

Additionally, sulfur content determines refinery cost being as low sulfur crudes may not require hydrotreaters.

Crude oil is classified as light, medium, or heavy grade according to its measured API gravity.

- Light crude oil has an API gravity higher than 31.1° (i.e., less than 870 kg/m3)

- Medium crude oil has an API gravity between 22.3° and 31.1° (i.e., 870 to 920 kg/m3)

- Heavy crude oil has an API gravity below 22.3° (i.e., 920 to 1000 kg/m3)

- Extra heavy crude oil has an API gravity below 10.0° (i.e., greater than 1000 kg/m3)

Grades of crude oil are shown above in graphical form.

When someone calls asking how much a 10,000 barrel per day mini refinery would cost, my response is that it depends on:

- API gravity

- Sulfur content

- Products desired

- Sulfur specifications on finished products

- Ability to switch between different crudes

There are no two mini refineries that are alike. The ability to switch between light and heavy crudes means that one crude may require a larger naphtha hydrotreater, a larger naphtha reformer and a larger diesel hydrotreater whereas the other may not. We typically analyze many crude scenarios for your mini refinery to determine the best configuration and process unit sizes during the feasibility study which is performed at the beginning of any new project.

Let’s look at three variations of mini-refineries:

- A simple topping refinery

- A hydro skimming refinery with naphtha and diesel hydrotreaters

- A hydro skimming refinery with naphtha and diesel hydrotreaters and naphtha reformer

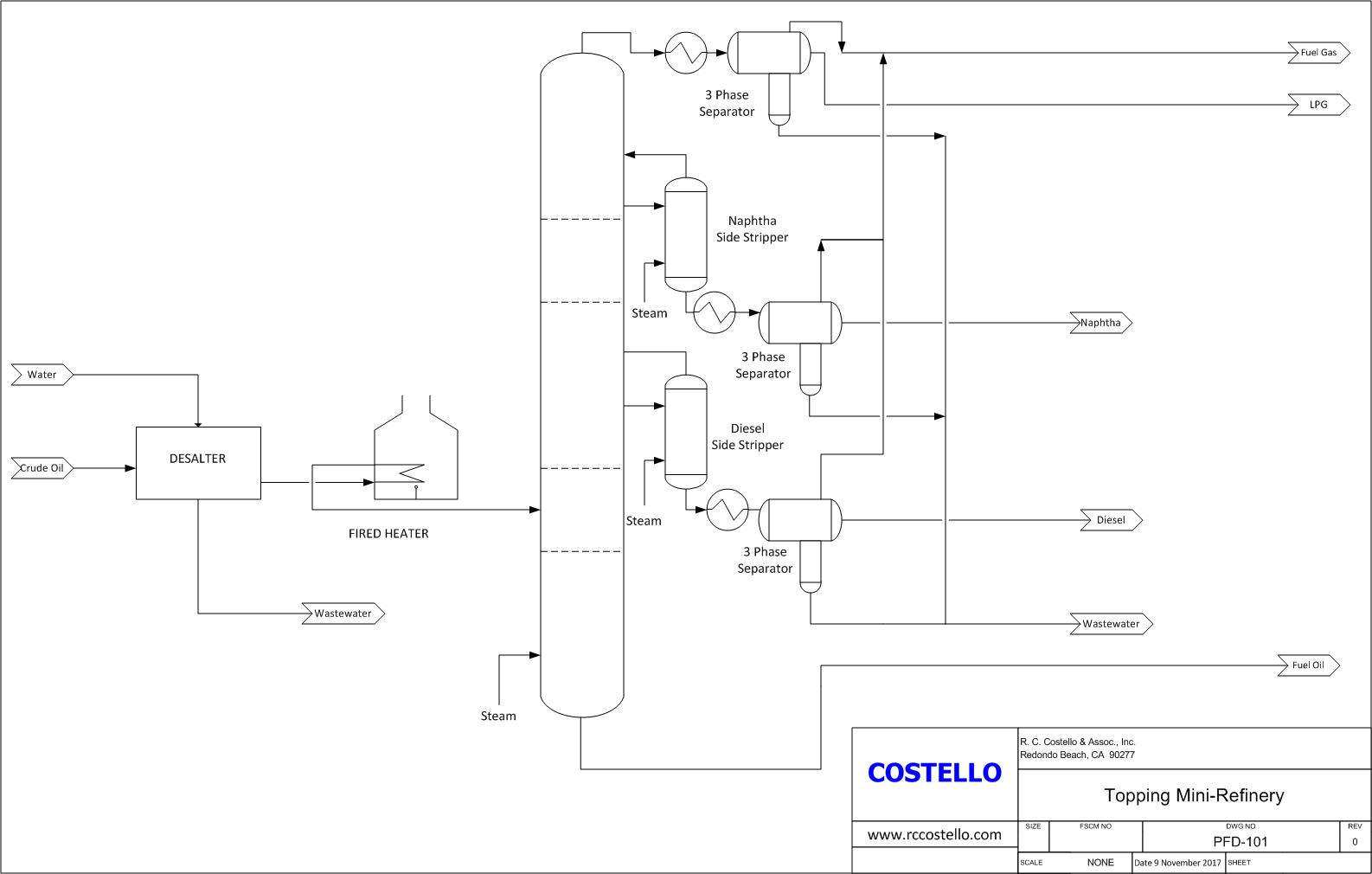

For the simple topping refinery, we have a gas fired heater to heat the crude before the atmospheric distillation unit, as shown below in PFD 101.

In PFD 102, we have all of the above from PFD 101 plus a naphtha hydrotreater, diesel hydrotreater and hydrogen plant.

In PFD 103, we have all of the above from PFD 102 minus the hydrogen plant plus a naphtha reformer. The hydrogen plant is not needed due to the naphtha reformer providing hydrogen for the naphtha and diesel hydrotreaters.