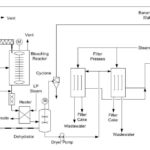

Overview In this fifth and final installation on biodiesel production we will cover biodiesel purification. Biodiesel Purification by Distillation There are two distinct process for biodiesel purification. One is removal of methanol by distillation and the other is removal of glycerin and the sodium methylate catalyst by ion exchange. The crude biodiesel product is preheated … [Read more...]

Transesterification – Biodiesel Part 4

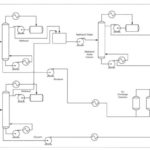

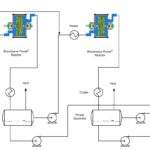

Overview The transesterification unit is designed to produce ASTM grade biodiesel by reacting low FFA oil or preesterified oils with excess methanol in the presence of a sodium methylate catalyst. Evaporator An oil drying system (Evaporator not shown) removes water and methanol after the esterification unit but prior to the transesterification system. The recovered … [Read more...]

Degumming of Feedstocks – Part 2

1. Overview The Degumming of biodiesel feedstocks process is necessary prior to the esterification and transesterification processes. Typical crude degummed oils have had their Hydratable Phospholipids (HPLs) removed by a simple water wash process. We typically accomplish this at the crushers facility. However, a typical soybean oil contains both hydratable … [Read more...]

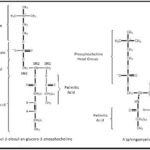

Understanding Biodiesel Chemistry – Part 1

In this 5 part blog series on Biodiesel Production, we will discuss the following 5 areas over the next 5 weeks: Chemistry Degumming Esterification Transesterification Purification When starting with crude degummed oils that have not been alkali refined, then step one is usually performed by the crusher and steps 2, 3 and 4 by our Biodiesel Technology. 1. … [Read more...]