Applied Catalysts is offering Catalytic Reactor Units for process intensification of Catalytic processes using their proprietary ACMC® activated carbon monolith catalyst technology. These modular turn-key systems offer enhanced productivity, selectivity and lifetime for Hydrogenation and other catalytic chemistries. Chemistry that is not equilibrium limited can be converted … [Read more...]

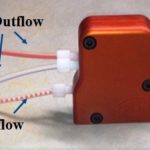

Miniature Membrane Separators and Separating Organic Solvents

Introduction to Membrane Separators Zaiput Flow Technologies’ patented liquid‐liquid/liquid‐gas miniature membrane separators enable liquid extraction in flow chemistry‐based processes and provide a solution for typical batch‐based liquid extraction steps (i.e., slow settling time/separation of emulsions, elimination of the need to run batches at half capacity to … [Read more...]

Transesterification – Biodiesel Part 4

Overview The transesterification unit is designed to produce ASTM grade biodiesel by reacting low FFA oil or preesterified oils with excess methanol in the presence of a sodium methylate catalyst. Evaporator An oil drying system (Evaporator not shown) removes water and methanol after the esterification unit but prior to the transesterification system. The recovered … [Read more...]

What is the Future of the Nelson-Farrar Cost Indexes?

The Nelson-Farrar Cost Indexes The Nelson-Farrar Cost Indexes were started by Dr. W. L. Nelson and Dr. Gerald L. Farrar. The indexes were calculated and published in every issue each month by the Oil & Gas Journal and with quarterly summaries in the January, April, July, and October issues. The indexes were originally named the Nelson Cost … [Read more...]

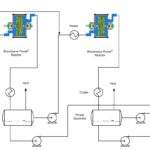

CHEMCAD Dynamics for Operator Training

CHEMCAD Dynamics is a remarkable tool for operator training. The example shown is a distillation column that looks like a Piping & Instrument Diagram. Each control loop can be modified by changing the proportion, integral and derivative values. The model responds similarly to a plant distillation column. Liquid holdup in the column, heat exchangers and even piping can … [Read more...]