Applied Catalysts is offering Catalytic Reactor Units for process intensification of Catalytic processes using their proprietary ACMC® activated carbon monolith catalyst technology. These modular turn-key systems offer enhanced productivity, selectivity and lifetime for Hydrogenation and other catalytic chemistries. Chemistry that is not equilibrium limited can be converted … [Read more...]

Miniature Membrane Separators and Separating Organic Solvents

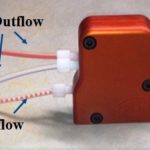

Introduction to Membrane Separators Zaiput Flow Technologies’ patented liquid‐liquid/liquid‐gas miniature membrane separators enable liquid extraction in flow chemistry‐based processes and provide a solution for typical batch‐based liquid extraction steps (i.e., slow settling time/separation of emulsions, elimination of the need to run batches at half capacity to … [Read more...]

Scaleup of Chemical and Pharmaceutical Plants

This article will discuss the scaleup of chemical and pharmaceutical plants. Introduction The blog will discuss only small continuous processes in the chemical industry and flow chemistry (continuous) processes in the pharmaceutical industries. COSTELLO gets involved when the laboratory chemistry has been completed and the client is ready to consider a continuous process. … [Read more...]

Biodiesel Purification – Final Part 5

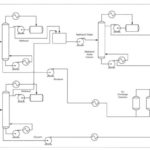

Overview In this fifth and final installation on biodiesel production we will cover biodiesel purification. Biodiesel Purification by Distillation There are two distinct process for biodiesel purification. One is removal of methanol by distillation and the other is removal of glycerin and the sodium methylate catalyst by ion exchange. The crude biodiesel product is preheated … [Read more...]

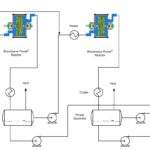

Transesterification – Biodiesel Part 4

Overview The transesterification unit is designed to produce ASTM grade biodiesel by reacting low FFA oil or preesterified oils with excess methanol in the presence of a sodium methylate catalyst. Evaporator An oil drying system (Evaporator not shown) removes water and methanol after the esterification unit but prior to the transesterification system. The recovered … [Read more...]