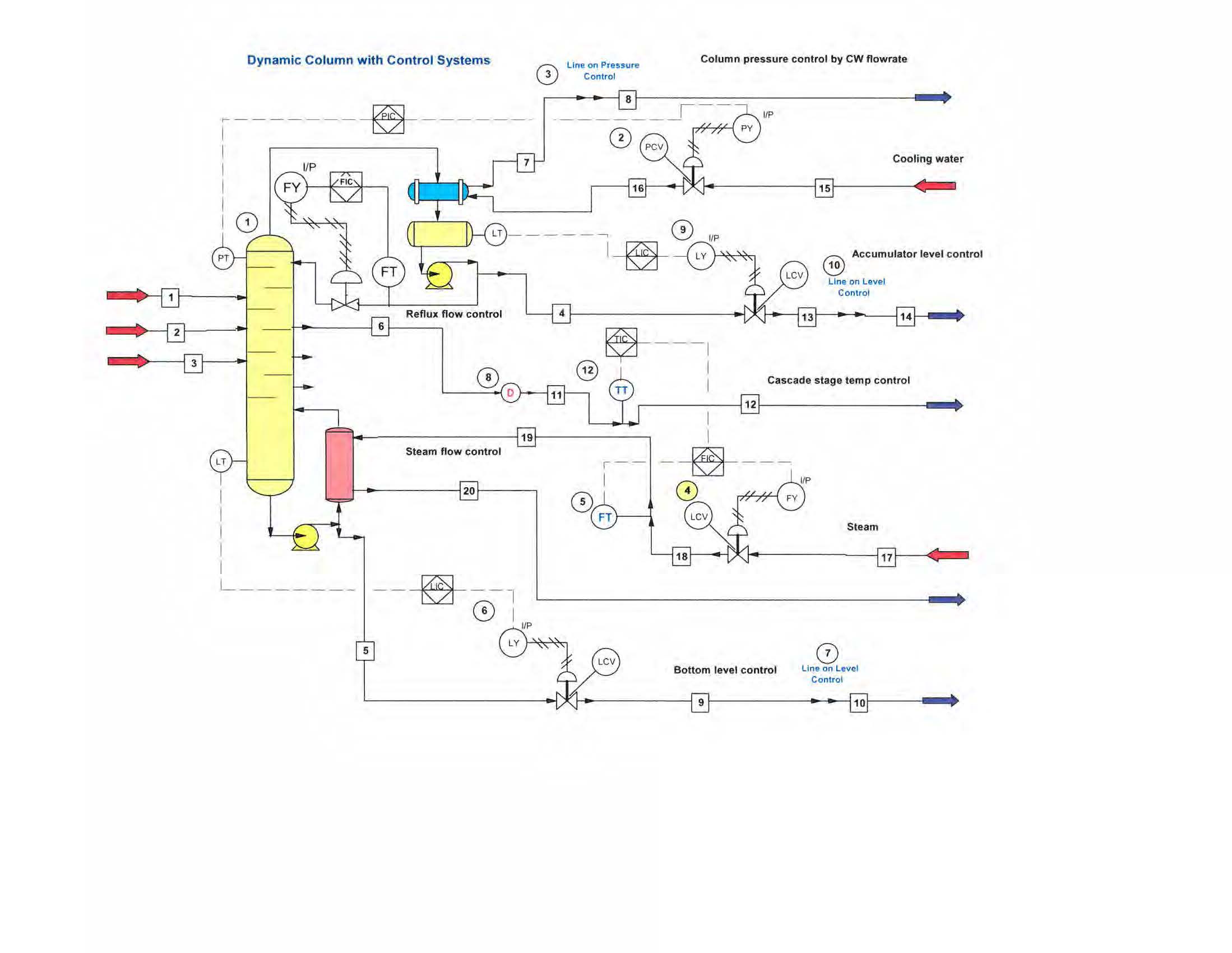

CHEMCAD Dynamics is a remarkable tool for operator training. The example shown is a distillation column that looks like a Piping & Instrument Diagram.

Each control loop can be modified by changing the proportion, integral and derivative values. The model responds similarly to a plant distillation column.

Liquid holdup in the column, heat exchangers and even piping can be added to the simulation so that the control loops respond just like the column in real time.

Prior to a new technology being brought on line, operators can be trained on a PC running ChemCad Dynamics with a simulation of the new process.

The operator being trained can see how the plant will respond to changes in level, flow and pressure set points on the various controllers.

Note that this simulation looks more like a P&ID using International Society of Automation (ISA) Standards for the instrumentation and controls than a simulation or a Process Flow Diagram.

Process failures can be created on the computer instead of the actual plant.

Sometimes changes can be made to the control logic prior to startup from the information learned in the Dynamic simulation such as this one.

The DCOLUMN dynamic unit operation

CC-DCOLUMN is a module within the CHEMCAD system. As such, it uses all the features which are fundamental to the system. These include:

- The flowsheet drawing features.

- The data input facilities.

- The CHEMCAD physical properties database.

- All thermodynamic options and data available in the CHEMCAD Suite.

- Output facilities such as viewing, plotting, and reporting.

- Regression facilities for physical properties, phase equilibrium, and electrolytes.

- Equipment sizing tools.

- Safety relief design and evaluation.

- Units operations that are common in both steady-state and dynamic simulations. These include calculator, component separator, controller, divider, Excel UnitOp, fired heater, flash vessel, heat exchanger, LLV flash, mixer, node, phase generator, pump, stream reference, valve.

- Sensitivity analysis.

- VBA and OPC connectivity.

- The on-line Help System