Biofuels

Based on numerous site assessments, one plant design does not fit every situation. Our engineering services determine exactly what is needed for your facility.

COPureSM

COPureSM Carbon Monoxide Purification Technology

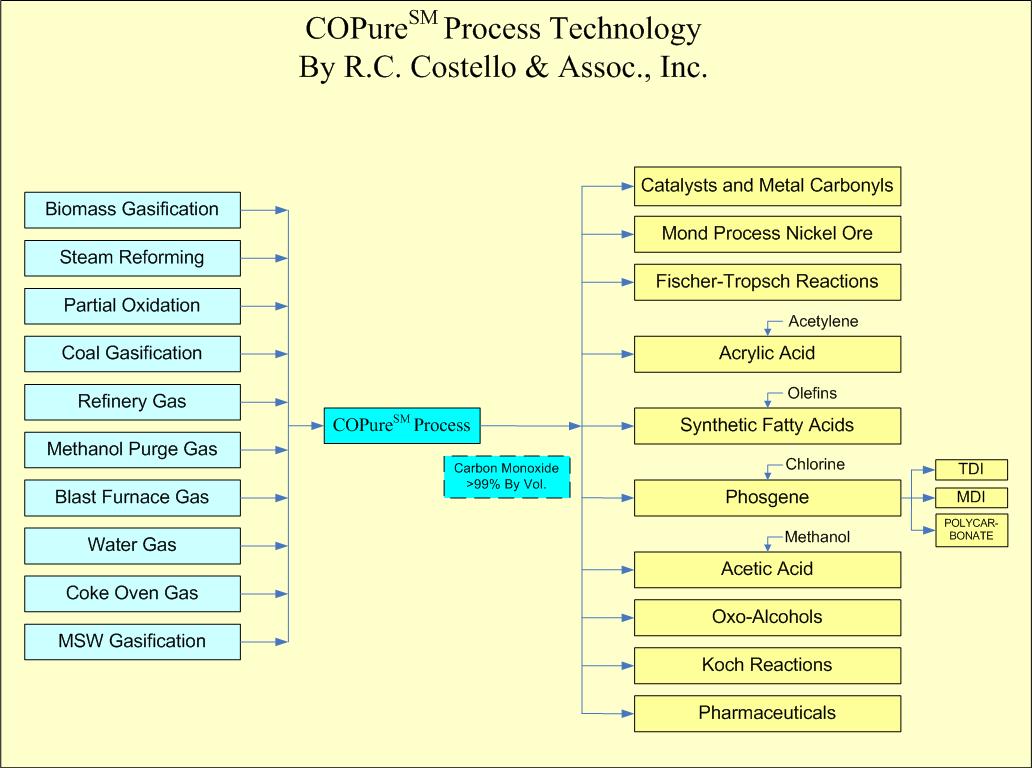

The block diagram below lists many sources of carbon monoxide gas. It also shows many uses of carbon monoxide gas including Fischer-Tropsch reactions.

COSTELLO provides design and technology for the purification of Carbon Monoxide gas with COPureSM . This technology provides a unique low cost solution to carbon monoxide recovery. Process improvements have made COPureSM a highly reliable source of carbon monoxide for downstream manufacture of chemicals and pharmaceuticals. COPureSM can be considered whenever recovery of high purity carbon monoxide is required. This is especially the case when the feed gas contains significant quantities of nitrogen and/or carbon dioxide, which need not be removed.

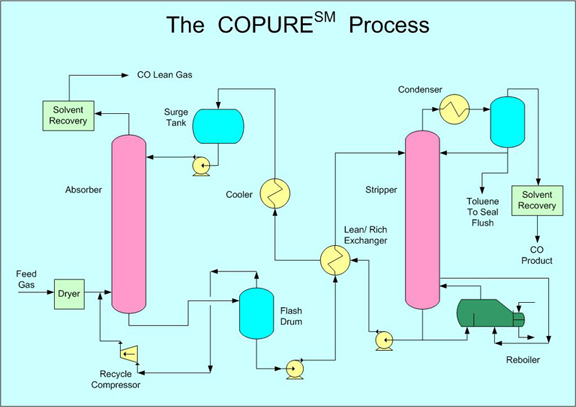

The COPureSM process selectively removes carbon monoxide by complexation/ decomplexation of carbon monoxide in a proprietary solvent containing cuprous aluminum chloride (CuAlCl4) dissolved in an organic liquid such as toluene.

Essentially the COPureSM process technology absorbs carbon monoxide and slips carbon dioxide, nitrogen and other gases. Typical product recovery is 98%, and typical purity is 99%. (Higher recoveries and purities are achievable.)

The COPureSM process may contain various post treatment or pretreatment steps that may include, compression, hydrogenation, dehydration, hydrogen sulfide removal, carbon dioxide removal etc. that are optimized for your process and plant configuration. For example if you were going to perform a Fischer-Tropsch reaction then purification of hydrogen and recombining it with the purified carbon monoxide would be included in the process.

The basic COPureSM process is shown below.

The COPureSM system has a number of advantages and attractions compared with competing technologies, i.e. cryogenic carbon monoxide recovery, and absorption by ammoniacal copper liquor:

COPureSM recovers carbon monoxide in almost quantitative yields and at high 99+ % purity

1. COPureSM can handle, without pretreatment, feeds containing synthesis gas components such as hydrogen, carbon dioxide, methane and nitrogen.

Cryogenic systems need to completely remove the carbon dioxide prior to carbon monoxide separation to prevent solid freeze up in the extremely cold environment.2. Cryogenic processing has great difficulty in recovering pure carbon monoxide when relatively large volumes of nitrogen are present due to carbon monoxide and nitrogen having very similar boiling points which are -191.5 °C and -195.79 °C respectively.

3. COPureSM operation does not depend on high pressure or temperature extremes for effective removal of carbon monoxide from gaseous mixtures as does cryogenic processing

4. The COPureSM solvent has a high absorption capacity.

5. COPureSM solvent is non-corrosive; therefore carbon steel can be used throughout with only minor exceptions

6. Most equipment can be fabricated locally, saving on foreign currency requirements, import duty and shipping costs.

COPureSM replaces COSORB® and COSORB® II 1 with additional innovation as follows:

1. Extensive pretreatment to remove undesirable components

2. Indirect cooling and heating.

3. Management system for solids (precipitation as a result of reaction

with undesirable components).4. Improved metallurgy in key locations

5. Klaren Self Cleaning Reboiler

6. Blending of the CO with the original hydrogen gas to the specified H2 : CO Ratio.

7. Sealless pumps

1 COSORB is a registered trademark of Tenneco Chemicals

LINKS

The Return of a Classic to Fuel Production

Development of the Modern Fischer-Tropsch Process

Green Diesel from Biomass via Fischer-Tropsch Synthesis

Please call for further information

R.C. Costello & Assoc., Inc.

1611 S. Pacific Coast Highway, Suite 302

Redondo Beach, CA 90277

Tel: (310) 792-5870, Fax: (310) 792-5877

E-MAIL: rcca[at]rccostello.com

COSTELLO

Consulting Engineers