Process Design

Costello designs mini refinery plants using both new and refurbished process units, many using

a skid-mounted modular structure, installed on concrete slab foundations

Mini Refinery Plant Design

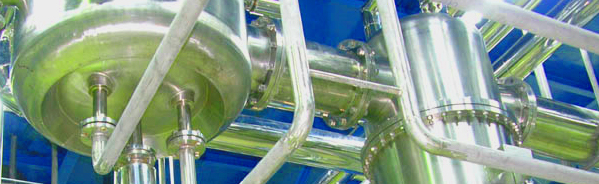

Costello designs mini-refinery plants using both new and refurbished process units, many using a skid-mounted modular structure, installed on concrete-slab foundations. When building a new plant, process equipment typically represents approximately 20% of the capital costs. Smaller unit operations are made possible by modular mini-plant designs, translate into a more compact plant with; and have less structural steel, piping, conduit and wire. The of the equipment may even allow savings on concrete foundations. Overall, modular or mini-plants means less-expensive plants with smaller footprints. In addition, many mini-plants are designed using refurbished process equipment, which can lower costs even further and accelerate the completion schedule.

Benefits of Mini Refineries:

• Accelerate project deadline;

• Enhanced quality control;

• Reduced energy use;

• Decreased capital expenditure;

• Smaller plant footprint (area);

• Fieldwork reduction;

• Reduced need for onsite skilled labor;

• Quicker financial returns for installed plant;

• Improved safety.

Who Can Benefit from Building a Mini Refinery?

Designing mini-refineries from the simplest straight run diesel production plants to more sophisticated hydro-treating refineries are increasingly becoming a flexible and cost-effective option for fuel producers in smaller, less-accessible areas. In this niche market there is a need to adapt rapidly to satisfy local fuel needs. With new oil fields being discovered all the time, these plants can be easily moved from one location to the next or transformed into larger or redesigned plants. This gives the fuel industry low capital costs and a fast turnaround time, thus bringing them rapid returns on their cost/barrel investments.

Why Hire Costello to Design your Mini Refinery?

Costello's engineering firm designs modular mini-refineries sized from 2,000 to 20,000 barrels per day. Most other refinery plant engineering firms are too large to deal in these smaller capacities, with typical projects in the tens of thousands of barrels/day. Our plant designs are customizable. Our seasoned engineers can incorporate the best new and used process equipment to create the most advanced mini-refinery for your needs.

Our mini-refineries can produce a variety of products from naphtha, gasoline, jet fuel and diesel. These process units are also designed for efficient processing of various crude products. In addition, vacuum tower bottoms can easily be converted to paving grade asphalt.

Let Costello work with you to design and build the refinery that meets your quality requirements on schedule and within budget.

For typical process flow diagrams on mini-refineries click here.

Please call for further information

R.C. Costello & Assoc., Inc.

1611 S. Pacific Coast Highway, Suite 302

Redondo Beach, CA 90277

Tel: (310) 792-5870, Fax: (310) 792-5877

E-MAIL: rcca[at]rccostello.com

COSTELLO

Consulting Engineers

- Chemical Plant Design

- Biofuels

- Natural Gas

- Asphalt

- Sulfur

- Mini Refinery Plant Design

- Skid Mounted Plants

- Eliminating Bottlenecks

- Extraction Systems

- Flow Chemistry

- Flow Chemistry

- Download our White Paper on "What you should know about modular process plants.pdf

Oil & Gas Refining News

What's Happening Right Now